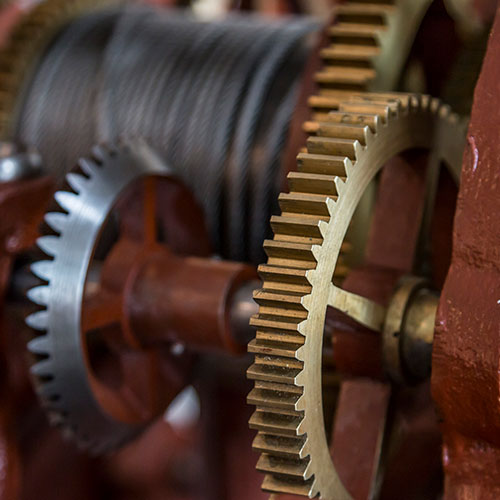

Pathway: Trades & Technical Studies

Do you like to work with your hands? Do you enjoy figuring out how things work and fixing problems?

The high-demand jobs in Trades & Technical Studies may be a good fit for you.

These programs study mechanics and construction of buildings, automobiles and more.

Trades & Technical Studies Program

The Trades & Technical Studies Program is designed for students who want to pursue a basic academic foundation. This program prepares individuals to apply technical knowledge and skills to repair and maintain an assortment of equipment across numerous careers.

The Pathway Program is a great option for students who want a broad understanding of this area, those who like to build upon their apprenticeship or credit diploma for job growth, as well as those who are unsure which Trades and Technical Studies program is best for them. Students can easily transfer into a specific Trades and Technical Studies program after starting here.

Automotive Technology Programs

Do you have a love of vehicles? Do you thrive at problem solving? The Automotive Technology program teaches students about engine construction, fuel and ignition systems, powertrains, brakes, transmissions, electronic and diagnostic equipment, basic auto body repair and more. These courses prepare students for the Automotive Service Excellence (ASE) certification exam.

Graduates may work in dealerships as well as independent and franchise shops.

Computer Numerical Control (CNC) Operator Program

In the CNC Operator Program, students will learn about manufacturing, precision measuring

and quality assurance. They will learn basic robot operation and programming. Students

will learn to use CNC lathes and mills in a hands-on environment in addition to computer

software.

Graduates typically work in manufacturing facilities or machine shops.

Diesel Technology Programs

Students in the Diesel Technology programs learn how to diagnose, adjust, repair, overhaul, and maintain any type of diesel engine. LCCC partners with Navistar, Volvo Trucks, PACCAR, DTNA and Caterpillar dealerships to stay current and maintain high-tech facilities. Students get hands-on training in addition to learning opportunities in the classroom and online.

Graduates from the program may find work with trucking companies, repair shops and manufacturers both locally and regionally.

Electrical Technology Program

The Electrical Technology program prepares students to construct, install, maintain,

troubleshoot and repair electrical circuits and systems. Students are part of a cohort,

remaining with the same peers throughout the program. They also have the opportunity

to participate in national competitions, such as Skills USA.

This program provides a route into an electrical apprenticeship with the International

Brotherhood of Electrical Workers or independent electrical contractors.

Foundations of Skilled Trades Program

The Foundations of Skilled Trades program prepares students to service, maintain, repair or install equipment for a wide range of industries. Students will explore areas like electronics, safety and mechanical maintenance fundamentals.

Graduates of this program may work for manufacturing, construction, maintenance and energy-related companies.

Industrial Maintenance Program

Enjoy working with your hands? Want a broad understanding of machines and electronics? Students in the Industrial Maintenance program learn the technical knowledge and skills to repair and maintain machinery and equipment such as pumps, motors, conveyor systems, production machinery, refinery and pipeline distribution systems. Students are part of a cohort, remaining with same peers throughout the program. They also have the opportunity to participate in national competitions, such as Skills USA.

Graduates of this program may work for manufacturing, construction, maintenance and energy-related companies.

Machine Tool Technology Program

The Machine Tool Technology Program provides initial training to students on manufacturing technology, including manual mills and lathes. Students will learn to read a blue print, apply relevant mathematical formulas, and use precision measuring tools.

The Machine Tool Technology Credit Diploma provides training for entry-level employment in a manual machining environment.

Welding Programs

Ready to work with fire? Students in the Welding program learn about welding machines, weld processes and hands-on welding proficiency. Students develop skills in blueprint reading, weld inspection and computer-aided drafting. Students are part of a cohort, remaining with same peers throughout the program. They also have the opportunity to participate in national competitions, such as Skills USA.

Graduates from this program may find work as a welder, assembler, machine operator, and construction or manufacturing welding technician.

Wind Energy Program

Learn the critical skills needed to become a successful technician in the rapidly growing wind industry. Students in this one-semester program will learn about installing, inspecting, maintaining, operating and repairing wind turbines. A combination of classroom instruction and hands-on training allows students to quickly turn concepts into valuable work experience.

Graduates typically work for energy companies and wind turbine maintenance companies in the west or Midwest regions of the country.